So I’ve mentioned in the weekly status reports that we had a significant issue with the flat roof at Mintwood. This post just shares a bit more info on that saga.

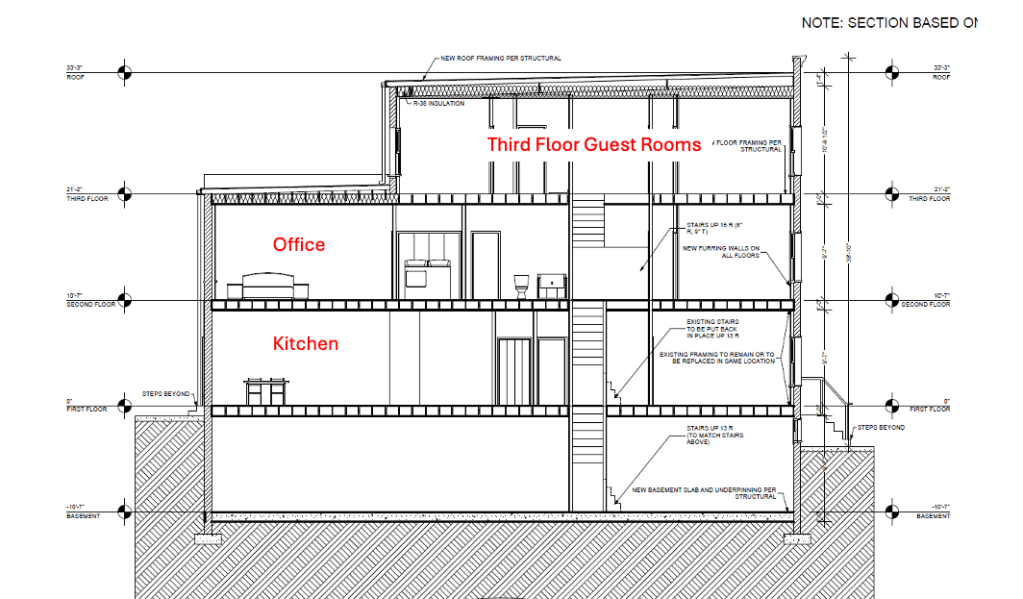

When we bought the property in 2020, we knew it needed a new roof. In fact, one of the first things we did was to have a company come and replace the flat roof on both the main building (over the third floor guest rooms) as well as the bump out that houses the office and the kitchen. (See image below, where the front of the house is at the right) We had three bids, and went with the “middle” bid of $12,250, so we weren’t chasing the cheapest solution. We went with a EPDM 60, a very durable roofing product that is often installed on flat roofs like our.

In the process of doing the rest of the renovations in 2021, we ended up with other roofers working on the mansards on the third floor. Every single crew that came to bid the mansard work commented negatively on the EPDM work. At the time, I chalked it up to professional squabbling, but I should have paid more attention. One of the issues they consistently raised was the installation of the drip edge over the office, and I actually paid an additional $2,500 to the mansard crew to address the drip edge issues in that area.

By the fall of 2023, I had a couple of concerns about the roof and I reached out to the roofing company that did the installation. Specifically:

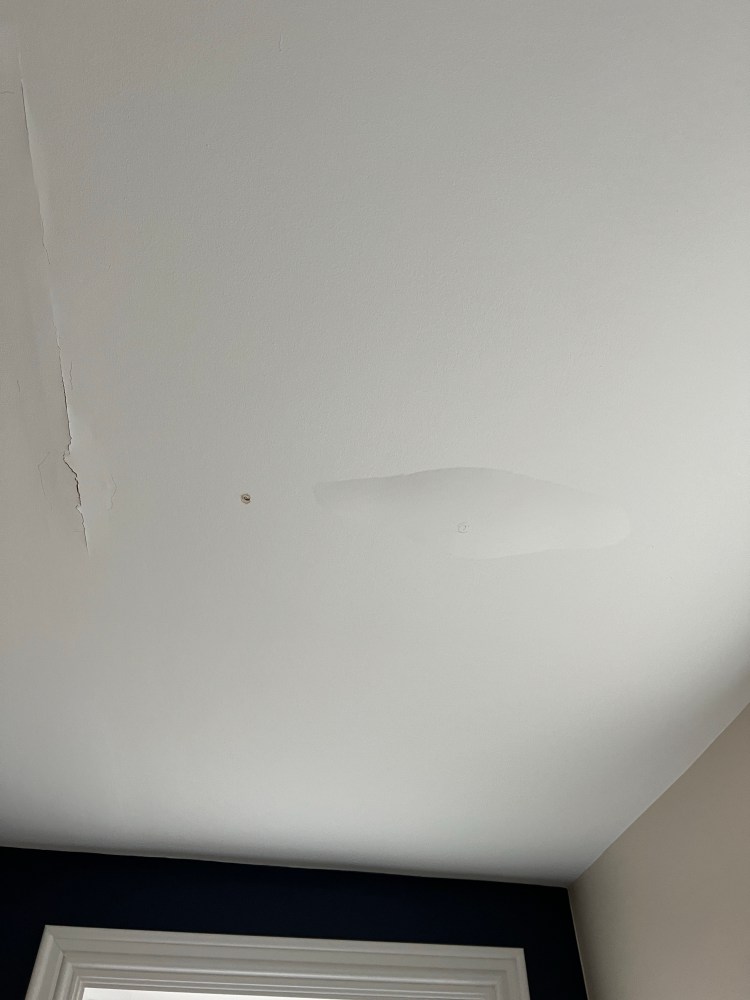

- We started noticing a linear mark in the plaster in the office. Eventually it became a ~36″ line, looking like the drywall compound was failing. We also saw a similar mark in the back guest bedroom on the third floor. I marked it off with a pencil, and for a while it seemed stable. That would eventually change…

- We’d had a large windstorm, and the drip edge they installed along the parapet wall in the front part of the house (above the front guest bedroom) had torn loose completely.

It took a bit of back and forth, but eventually they sent out a crew. By the time they’d come out, we were officailly getting real water through the ceiling in the office.

I was less than impressed with the repair crew- they seemed to be trying to do the absolute minimum work. For example, they repaired only the specific section of the failed drip edge on the main roof, even though the rest of it was installed using the same (faulty) technique. I had to show them photos taken *while they were there* to prove that they hadn’t done the rest of the edge. Then they dug in and said “that’s all the boss wants us to do.” I called their bluff and phoned the office and they finally relented and fixed the rest of the edge.

Over the office, they focused their work on a “lumpy” portion of the roof. When they did the initial installation, there were remnants of a drain pipe protruding through the decking. Rather than cutting that down, they just rolled the EPDM over it and caulked the seams. Since that was fairly close to where the mark was on the ceiling, they zeroed in on that “lump” as the cause of the leak. The smeared more caulk around the seams and said that would solve the problem.

(Taken just before the water came pouring in)

Needless to say, after the repair crew left, the problem didn’t improve. In fact, it got worse. The “crack” got longer, and eventually we had a full-on failure of the drywall. Every time it rained, we had to rush to get buckets in the right places in the office. Even that wasn’t enough to avoid a big stain the carpet and who knows what other damage. With no confidence in the old crew, I called in someone else.

It’s worth acknowledging that getting this second crew in was not simple. They came quickly and provided a bid, which I promptly signed, but then they disappeared for over 2 months. It turns out there were some tornados in Ohio, and they had all hands on deck to work on the insurance jobs that result from that type of event. I wasn’t thrilled, but there wasn’t much I could do.

In the estimating process, they’d identified a number of issues:

- There was some concern that the “old roofers” hadn’t used any primer in some spots, and in others, it appeared not to be enough.

- Every place a plumbing vent goes through the roof, there is a rubber “boot”. Think of it as an upside-down funnel. The boots were cut too short and were not properly secured, so water was 100% getting in around those areas.

- Near the chimney over the rear guest bedroom, the flashing was clearly installed incorrectly. They basically just glued the EPDM directly to the brick, with no flashing and no termination bar (T-Bar) to hold it in place. That had definitely failed.

- On the office roof, there were definitely issues with the “lump” – the caulking (just touched up a few months prior) was already cracking and failing. The team also pointed out a number of places where the EPDM layout had fold/ wrinkles. This doesn’t sound like much, but every place like that is an area where water can and will wick under the roofing surface.

- The main seam across the lower roof (where it joins the neighbor’s roof) had definitely been done incorrectly. They’d simply glued it down to the neighbor’s roof, and that neighbor’s roof turns out NOT to be compatible with EPDM glue. The heat/cool cycles of a couple of summers had pulled the seam completely open.

and yet another pipe in the corner

Overall, the foreman from the new crew summed up the prior work as “they’re a residential contractor doing rubber roofing, but they just don’t really know how. They don’t understand the details.”

What does all of this mean? The foreman from the new crew summed it up as “they’re a residential contractor doing rubber roofing, but they just don’t really know how. They don’t understand the details. They [weren’t trying to] give you a bad job, they just didn’t know.” If there was any doubt how bad it was, though, we found out when we stripped the old roof off the office. More than 70% of the substrate – the wood that is underneath the EPDM – was soaking wet. See photo below.

The repair team consisted of 5 guys, including a couple of guys who’d been doing this for decades. The same company does a large percentage of the commercial flat roofs in the Pittsburgh area (think: Eat-n-Park, McDonald’s, etc.). They offer a 5 year warranty on their workmanship and 15 years on materials. When I went back to look at the warranty on my prior contractor, it was only 12 months. Really? A 12 month warranty on a roof that should last 15-25 years? I totally missed that when I signed the original contract. Damn!!

They got to work across the entire building. On the main roof, they fixed all of the boots including putting a sealant behind the boot and then adjusting/ tightening the bands. They touched up a few places on the seams as well. The new crew raised some concerns about the mortar in the chimney, so I quickly pointed that. Once it had set up correctly, they were about to properly flash around it and install T-Bar as it should have been done.

On the lower roof, we did a complete tear off. They cut down the protruding pipes so that they were all below the surface. After putting down new substrate and insulation, they installed all new EPDM. The seam to the adjacent roof was done in a three-part lay-up (metal flashing bridging the seam, then adhesive EPDM on my side and a roofing pitch/ mesh tape layer on the other side. They also added new T-Bar where the lower roof meets the wall under the main roof- something the previous installers skipped completely.

I spent a fair bit of time talking to the crew leader. He’s an industry veteran, and was a union roofer for many years. We talked about what went wrong and how things are supposed to be done. He even pointed me to the industry standards, the National Roofing Association Handbook for Flat Roofs so that I could read up and ensure I was happy with what they’d done. No surprise that they’d done everything “by the book”. It’s also a great example of my preferred way to work with subcontractors- I want to know the on-site people are really experts, and share my passion for quality. These folks definitely checked that box.

Sometimes it is the little details that show you the team is focused on quality. For example, on the metal bridging the two roofs, they took the time to set a chalk line so they’d know they had the right amount of overlap on each side. They also slowed down so that we could fabricate and install a plywood substrate over the parapet wall, so that the edge was crisp and the roofing material didn’t just lay across it like wet lasagna. Even when they parked their truck- they had cardboard to put under the engine incase it dripped oil on my new driveway. Little details like this don’t guarantee a perfect job, but it tells you that someone is looking out for quality.

“just in case”

It’s now been about 3 weeks since the repair was done. We got a pretty good dump of rain today, and I’m happy to report that the inside of the house is completely dry. A cynic might say that the prior roof was good after the first rain too- but I have a much higher level of confidence in this repair job, and I look forward to working with this crew on my next project.

What a saga! Hope you’re dry now.

Bill Smith Phone: 303.814.8819 Mobile: 303.815.3955

>

LikeLike